Comprehensive Compressed Air Service

VALUE CHAIN >>>

Professional solutions in high quality pneumatic systems. Design, assembly, technical support and maintenance.

Comprehensive Compressed Air Service

CADENA DE VALOR >>>

Professional solutions in high quality pneumatic systems. Design, assembly, technical support and maintenance.

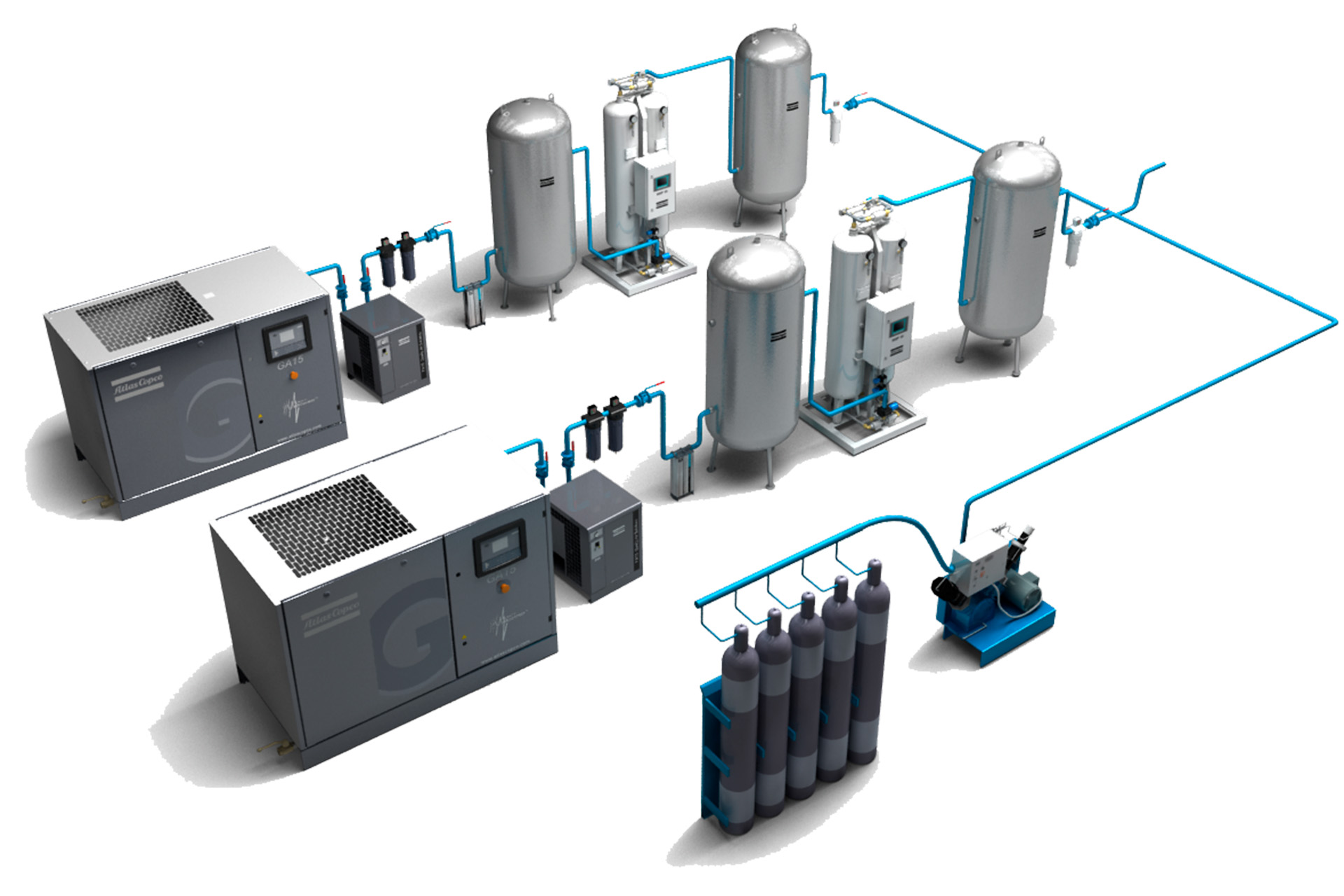

SERVICE SCOPE

Our compressed air service focuses on providing comprehensive solutions that go from a customized study of the customer's needs to the systems installation and maintenance.

This includes the evaluation of specific requirements to determine the type and capacity of the most suitable system. Once defined, we proceed to the supply and installation of the necessary equipment, guaranteeing compliance with all current regulations through the facilities' certification and legalization. In addition, preventive and corrective maintenance is provided to guarantee the optimal operation of the systems, as well as an after-sales service to ensure long-term customer satisfaction.

Project Phases

1. Requirements Assessment

- Initial Analysis: A detailed study of the client's specific requirements is carried out, considering factors such as the type of industrial processes, the volume of air required and the characteristics of the working environment.

- Customized Recommendations: Based on the analysis, recommendations are made on the most appropriate type of compressed air system, including capacity, type of compressor (e.g. screw, piston, etc.) and accessories required.

2. System Design

- Technical Planning: A technical design is prepared that includes the layout of equipment, piping and accessories, ensuring that the system is efficient and complies with safety and environmental regulations.

- Performance Simulation: In some cases, simulations can be performed to predict system performance under different operating conditions.

3. Supply and Installation

- Equipment Procurement: The necessary equipment and components are purchased, ensuring that they are of high quality and meet industry standards.

- Professional Installation: A team of specialized technicians carries out the installation of the system, ensuring that all components are properly integrated and working optimally.

4. Certification and Legalization

- Regulatory Compliance: The necessary steps are taken to certify that the installation complies with all local and national regulations, including obtaining permits and conducting safety tests.

- Documentation: The client is provided with all necessary documentation supporting the legality and safety of the installed system.

5. Preventive and Corrective Maintenance

- Maintenance Programs: Preventive maintenance plans are established that include periodic reviews, filter cleaning, and necessary adjustments to ensure continued system performance.

- Attention to Failures: In the event of failures or problems, corrective maintenance service is provided including quick diagnostics and repairs to minimize downtime.

6. After Sales Service

- Ongoing Support: Customer service is provided, including technical advice and resolution of questions about the operation of the system.

- Upgrades and Enhancements: Options are provided to upgrade or enhance the system as customer needs or available technology evolves.

APPLICATION AREAS

Compressed air has applications in a wide range of industrial sectors.

In general engineering, it is used for pressure testing and component cleaning, which is essential for maintaining product quality and safety. In the manufacturing and process industry, compressed air powers pneumatic tools and automated systems, improving production efficiency. In the food & beverage industry, it is used in packaging and product handling, ensuring hygienic standards. In medicine and pharmacopoeia, it is used in medical equipment and in the generation of gases required for clinical procedures. Finally, in construction and automotive, compressed air is essential for the operation of tools and equipment, as well as in painting and assembly processes.

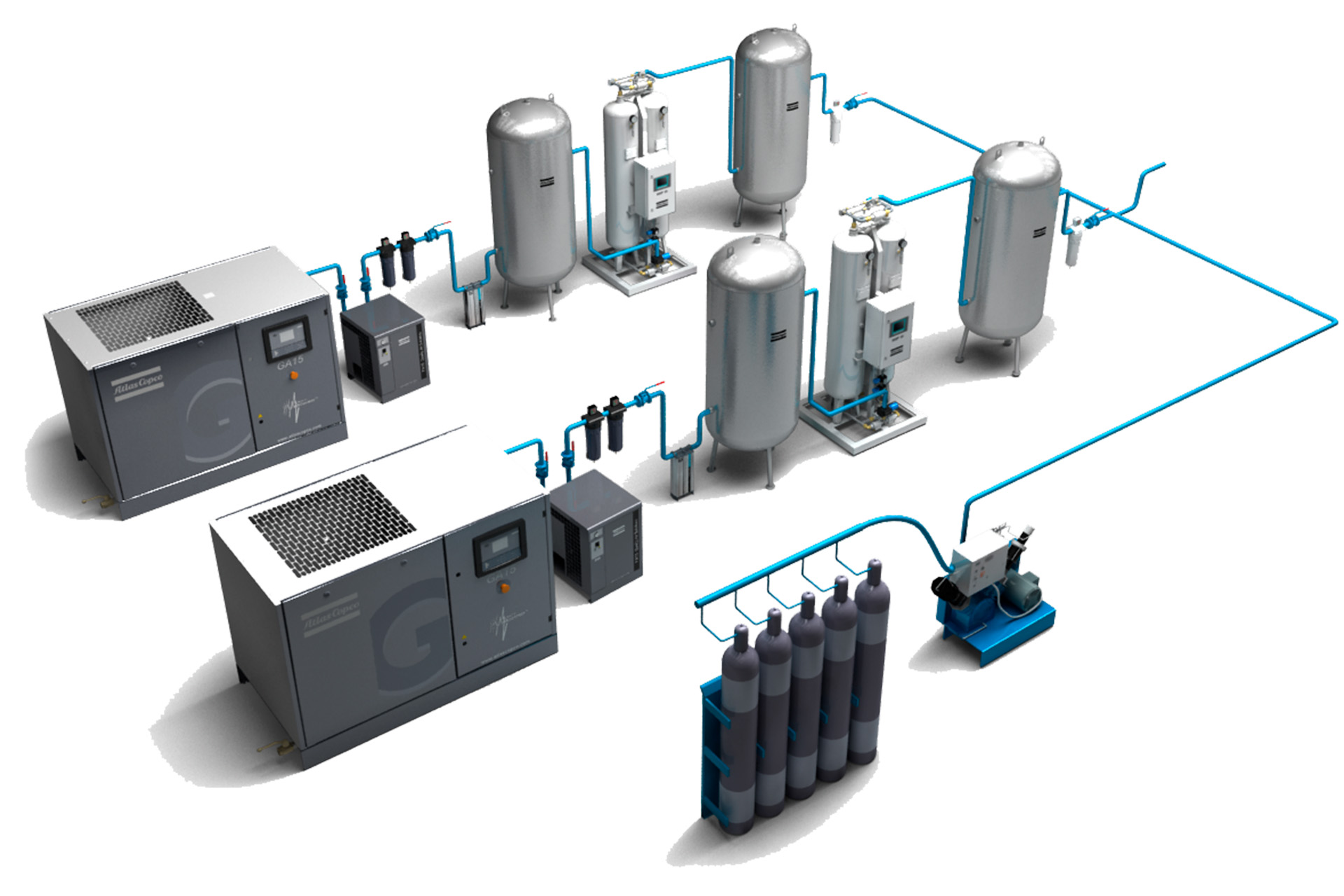

ALCANCE DEL SERVICIO

Our compressed air service focuses on providing comprehensive solutions that go from a customized study of the customer's needs to the systems installation and maintenance.

This includes the evaluation of specific requirements to determine the type and capacity of the most suitable system. Once defined, we proceed to the supply and installation of the necessary equipment, guaranteeing compliance with all current regulations through the facilities' certification and legalization. In addition, preventive and corrective maintenance is provided to guarantee the optimal operation of the systems, as well as an after-sales service to ensure long-term customer satisfaction.

Project Phases

1. Requirements Assessment

- Initial Analysis: A detailed study of the client's specific requirements is carried out, considering factors such as the type of industrial processes, the volume of air required and the characteristics of the working environment.

- Customized Recommendations: Based on the analysis, recommendations are made on the most appropriate type of compressed air system, including capacity, type of compressor (e.g. screw, piston, etc.) and accessories required.

2. System Design

- Technical Planning: A technical design is prepared that includes the layout of equipment, piping and accessories, ensuring that the system is efficient and complies with safety and environmental regulations.

- Performance Simulation: In some cases, simulations can be performed to predict system performance under different operating conditions.

3. Supply and Installation

- Equipment Procurement: The necessary equipment and components are purchased, ensuring that they are of high quality and meet industry standards.

- Professional Installation: A team of specialized technicians carries out the installation of the system, ensuring that all components are properly integrated and working optimally.

4. Certification and Legalization

- Regulatory Compliance: The necessary steps are taken to certify that the installation complies with all local and national regulations, including obtaining permits and conducting safety tests.

- Documentation: The client is provided with all necessary documentation supporting the legality and safety of the installed system.

5. Preventive and Corrective Maintenance

- Maintenance Programs: Preventive maintenance plans are established that include periodic reviews, filter cleaning, and necessary adjustments to ensure continued system performance.

- Attention to Failures: In the event of failures or problems, corrective maintenance service is provided including quick diagnostics and repairs to minimize downtime.

6. After Sales Service

- Ongoing Support: Customer service is provided, including technical advice and resolution of questions about the operation of the system.

- Upgrades and Enhancements: Options are provided to upgrade or enhance the system as customer needs or available technology evolves.

Áreas de Aplicación

Compressed air has applications in a wide range of industrial sectors.

In general engineering, it is used for pressure testing and component cleaning, which is essential for maintaining product quality and safety. In the manufacturing and process industry, compressed air powers pneumatic tools and automated systems, improving production efficiency. In the food & beverage industry, it is used in packaging and product handling, ensuring hygienic standards. In medicine and pharmacopoeia, it is used in medical equipment and in the generation of gases required for clinical procedures. Finally, in construction and automotive, compressed air is essential for the operation of tools and equipment, as well as in painting and assembly processes.

BENEFITS

-

Excellence

Latest technology and high efficiency equipment, with the consequent reduction of energy costs.

AIRNET® piping with 10 years warranty.

-

Productivity

Improved operational efficiency by optimizing industrial processes.

-

Cost Reduction

Thanks to proper maintenance that prevents failures and prolongs the useful life of the equipment.

-

Quality Improvement

Of the final product, since a constant and controlled supply of compressed air is essential to maintain production standards.

-

Safety

The implementation of these systems contributes to a safer and more sustainable working environment, in line with current trends towards environmental responsibility.

BENEFICIOS

-

Excellence

Latest technology and high efficiency equipment, with the consequent reduction of energy costs.

AIRNET® piping with 10 years warranty.

-

Productivity

Improved operational efficiency by optimizing industrial processes.

-

Cost Reduction

Thanks to proper maintenance that prevents failures and prolongs the useful life of the equipment.

-

Quality Improvement

Of the final product, since a constant and controlled supply of compressed air is essential to maintain production standards.

-

Safety

The implementation of these systems contributes to a safer and more sustainable working environment, in line with current trends towards environmental responsibility.