3D Prototyping for Tooling and Supplies Fixtures

VALUE CHAIN >>>

Customized CAD/CAM solutions for resolving technical challenges in production, assembly, and industrial maintenance areas.

3D Prototyping for Tooling and Supplies Fixtures

CADENA DE VALOR >>>

Customized CAD/CAM solutions for resolving technical challenges in production, assembly, and industrial maintenance areas.

SERVICE SCOPE

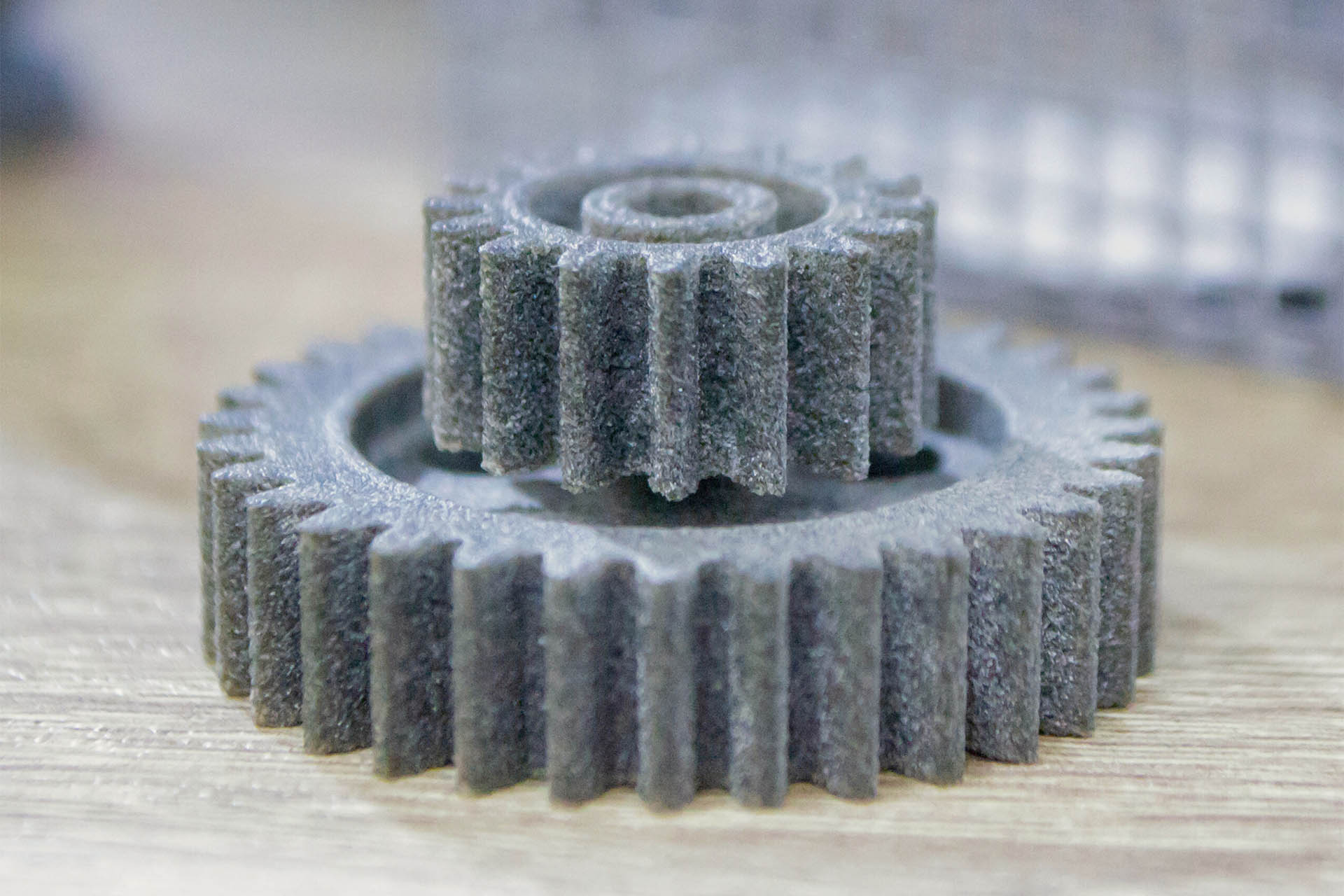

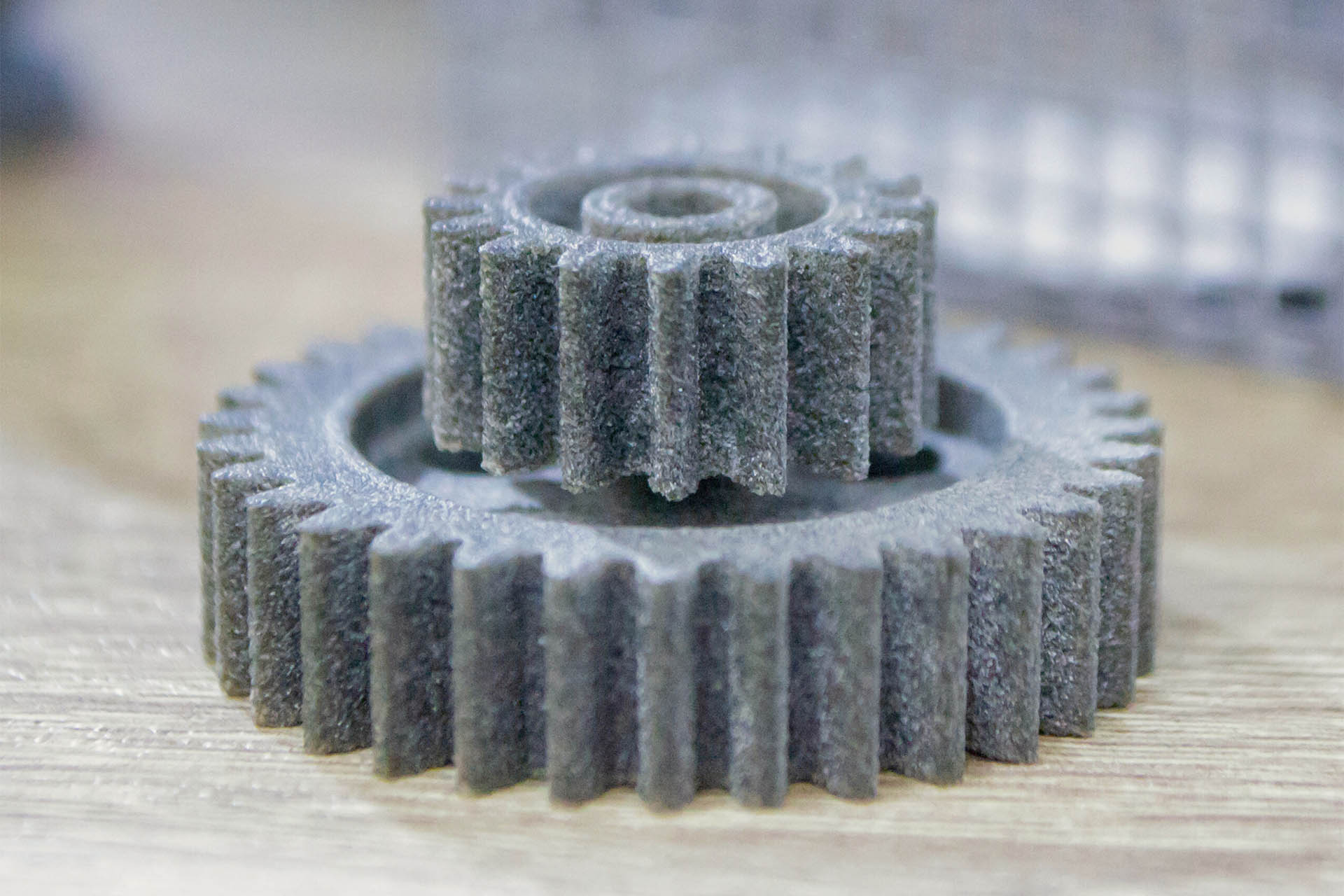

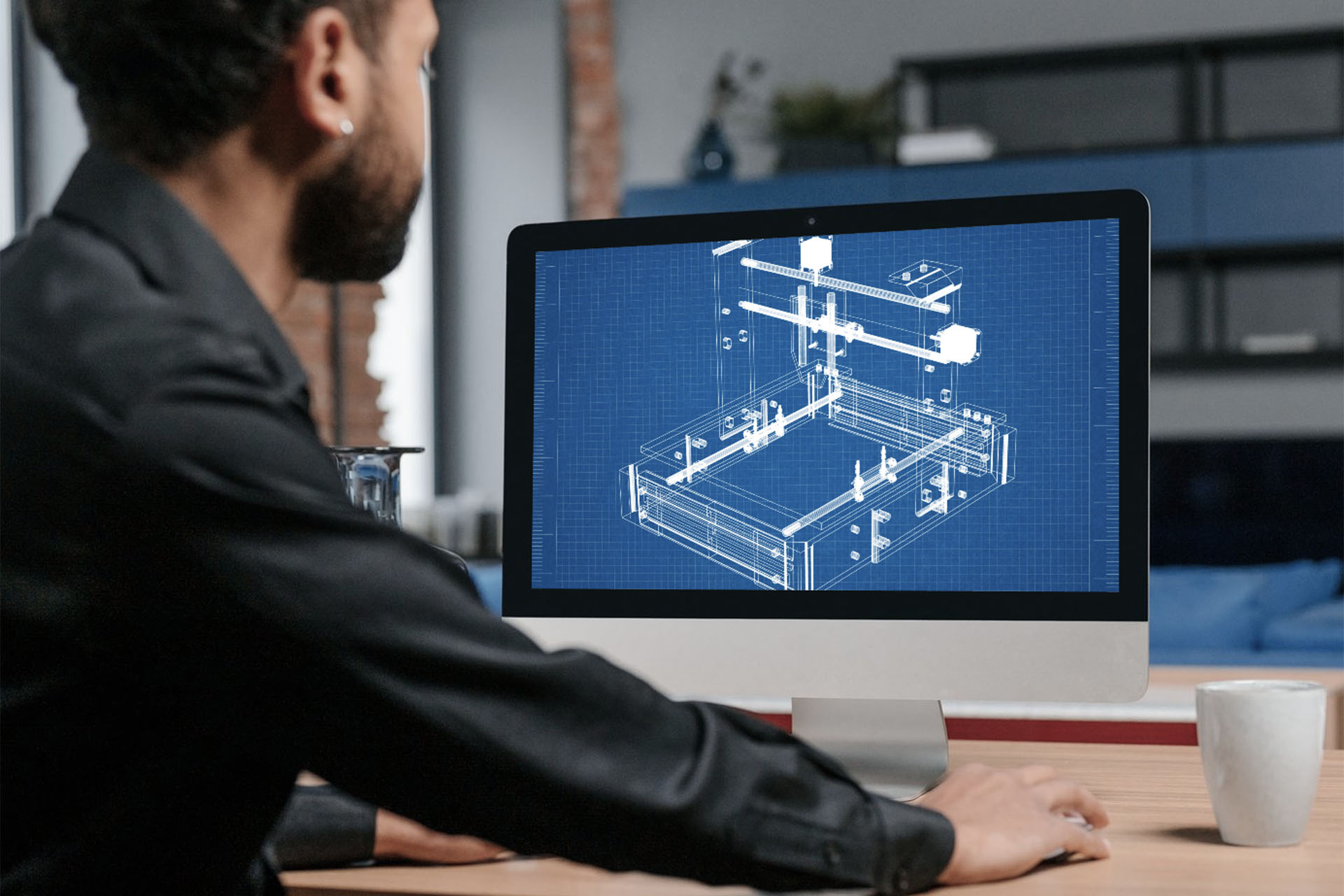

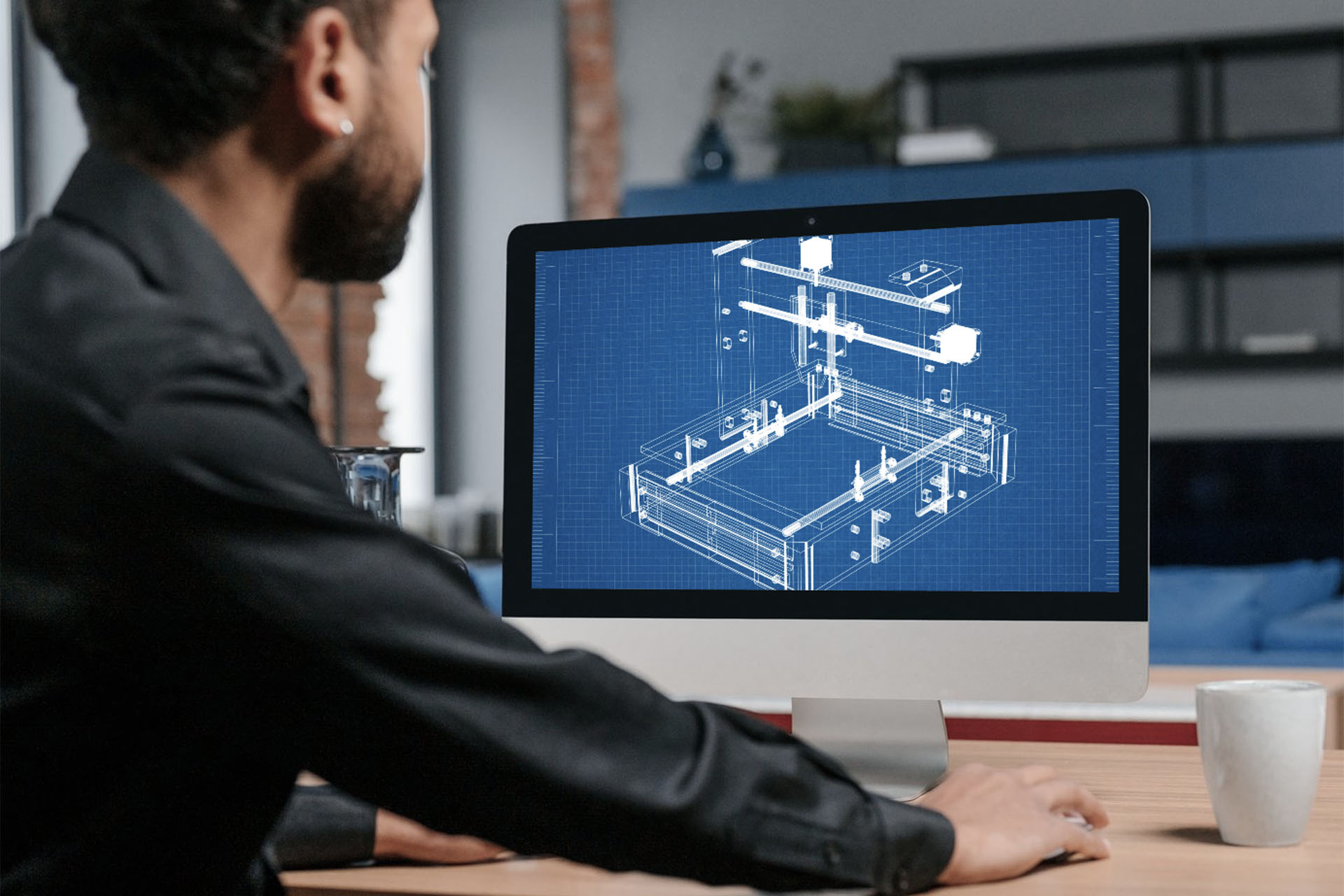

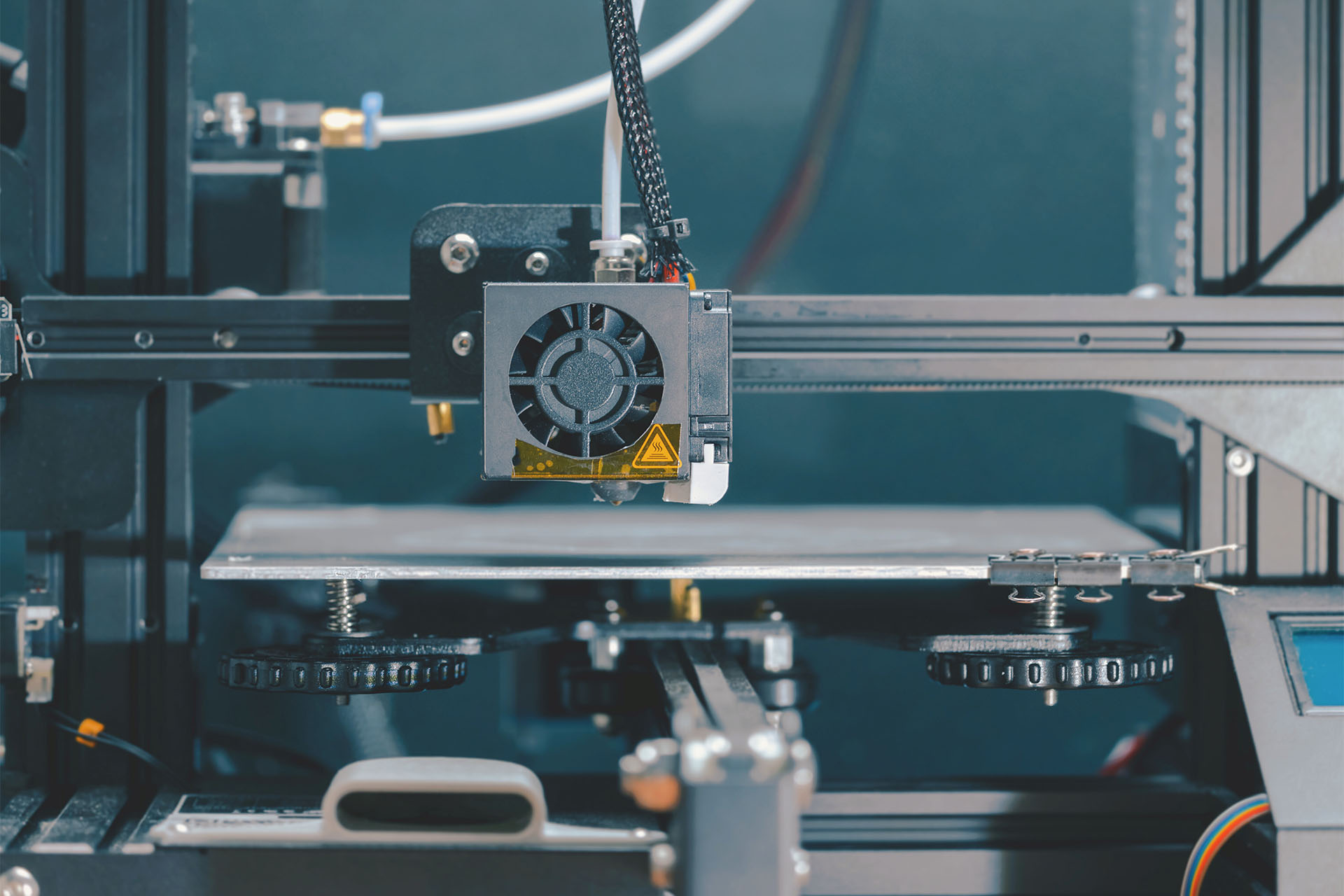

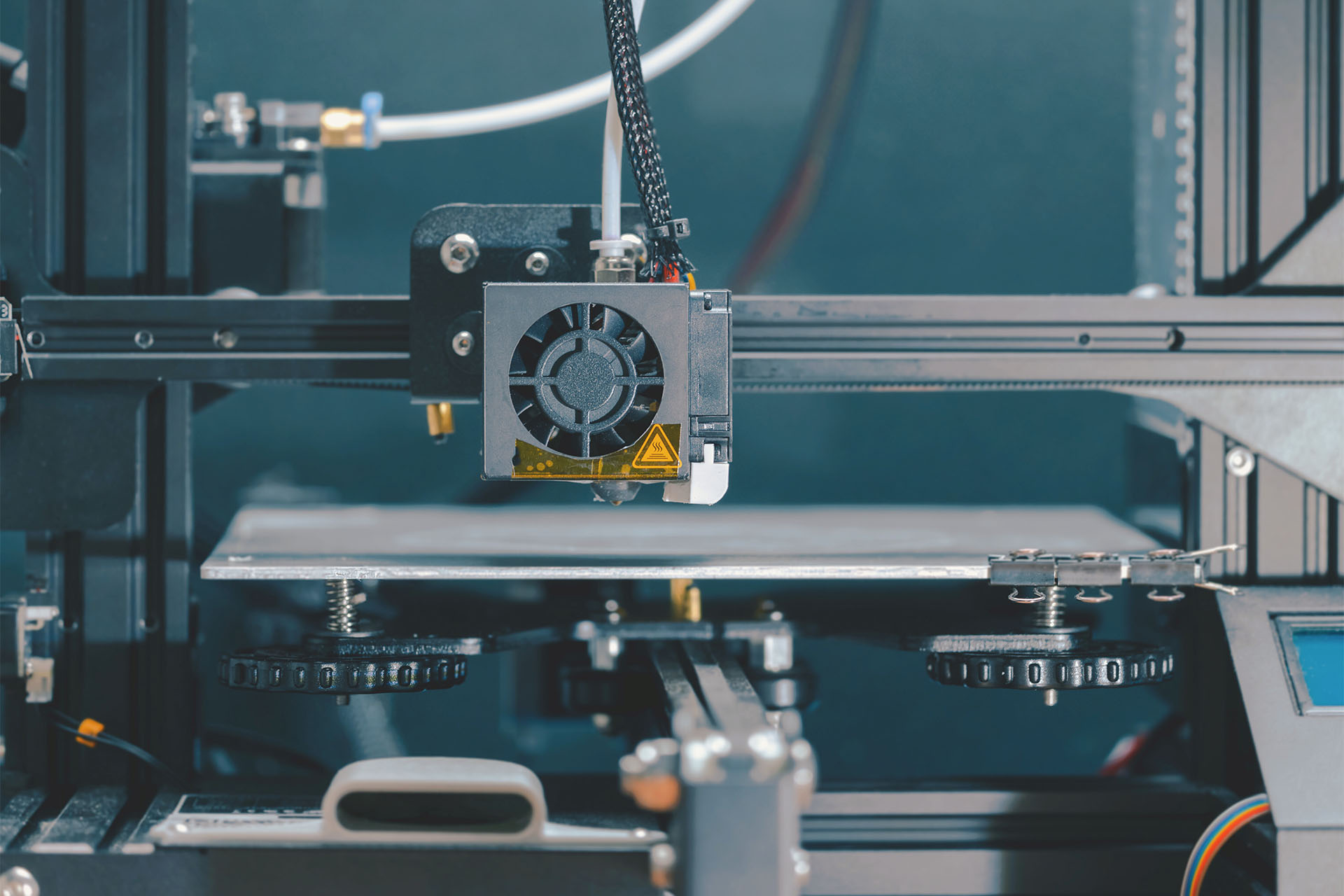

The Design, Prototyping, and 3D Printing Service for Tools and Fixtures is defined as a collaborative process involving engineering and production departments to develop customized solutions that address specific challenges in workshops or production lines.

This service leverages advanced digital tools, such as CAD software and 3D modeling, to design accessories and tools that enhance efficiency and functionality in industrial environments. Once the design is approved, a functional prototype is printed using 3D printing technology, allowing the client to validate the solution before mass-producing the tools or accessories in the required materials, such as aluminum or steel.

APPLICATION AREAS

- In the automotive industry, the design, prototyping, and 3D printing service is applied to the creation of specific tools and accessories for vehicle assembly, maintenance, and repair. This includes the development of customized templates for part alignment, clamping tools for delicate components, and prototypes of spare parts that allow manufacturers to validate designs before mass production. The ability to quickly adapt designs to changing market needs improves efficiency and reduces downtime on the production line.

- In the electronics sector, design and 3D printing are used to create tools that facilitate the handling and assembly of electronic components. This includes the production of precision tools for the placement of printed circuit boards, as well as prototypes of casings and supports that meet exact specifications. The ability to produce rapid prototypes enables companies to evaluate the functionality and aesthetics of products before launch, resulting in a more agile and efficient development process.

- The aerospace industry benefits from 3D design and prototyping for the creation of components and tools that meet strict safety and performance regulations. This includes the production of prototypes of critical parts for aerodynamic and functionality testing, as well as specialized tools for aircraft assembly. The ability to print with lightweight and durable materials allows manufacturers to optimize product performance, reducing weight and improving fuel efficiency.

- In the construction industry, the design, prototyping, and 3D printing service is applied to the development of specific tools and accessories that facilitate project execution. This includes the manufacturing of molds for prefabricated elements, alignment and fastening tools, and prototypes of architectural components. The ability to rapidly produce prototypes allows architects and builders to validate designs and make adjustments before final construction, resulting in greater efficiency and cost reduction in the building process.

ALCANCE DEL SERVICIO

The Design, Prototyping, and 3D Printing Service for Tools and Fixtures is defined as a collaborative process involving engineering and production departments to develop customized solutions that address specific challenges in workshops or production lines.

This service leverages advanced digital tools, such as CAD software and 3D modeling, to design accessories and tools that enhance efficiency and functionality in industrial environments. Once the design is approved, a functional prototype is printed using 3D printing technology, allowing the client to validate the solution before mass-producing the tools or accessories in the required materials, such as aluminum or steel.

Áreas de Aplicación

- In the automotive industry, the design, prototyping, and 3D printing service is applied to the creation of specific tools and accessories for vehicle assembly, maintenance, and repair. This includes the development of customized templates for part alignment, clamping tools for delicate components, and prototypes of spare parts that allow manufacturers to validate designs before mass production. The ability to quickly adapt designs to changing market needs improves efficiency and reduces downtime on the production line.

- In the electronics sector, design and 3D printing are used to create tools that facilitate the handling and assembly of electronic components. This includes the production of precision tools for the placement of printed circuit boards, as well as prototypes of casings and supports that meet exact specifications. The ability to produce rapid prototypes enables companies to evaluate the functionality and aesthetics of products before launch, resulting in a more agile and efficient development process.

- The aerospace industry benefits from 3D design and prototyping for the creation of components and tools that meet strict safety and performance regulations. This includes the production of prototypes of critical parts for aerodynamic and functionality testing, as well as specialized tools for aircraft assembly. The ability to print with lightweight and durable materials allows manufacturers to optimize product performance, reducing weight and improving fuel efficiency.

- In the construction industry, the design, prototyping, and 3D printing service is applied to the development of specific tools and accessories that facilitate project execution. This includes the manufacturing of molds for prefabricated elements, alignment and fastening tools, and prototypes of architectural components. The ability to rapidly produce prototypes allows architects and builders to validate designs and make adjustments before final construction, resulting in greater efficiency and cost reduction in the building process.

BENEFITS

-

Customization and Adaptability

The ability to design specific tools allows companies to tailor solutions to their particular needs, improving operational efficiency.

-

Reduction of Development Leadtimes

The use of 3D printing for prototypes accelerates the validation process, enabling quick adjustments before mass production.

-

Cost-Effectiveness

The production of custom tools and accessories can be more cost-effective than purchasing standard solutions, especially when specific modifications are required.

-

Improved Production Efficiency

Tools designed specifically for tasks on the production line can reduce cycle times and increase productivity.

-

Continuous Innovation

Collaboration with engineering and production departments fosters an environment of innovation, where new ideas and technologies can be explored to enhance processes.

-

Material Versatility

The ability to manufacture with different materials, such as aluminum and steel, allows companies to choose the most suitable option for their specific needs, ensuring durability and functionality.

BENEFICIOS

-

Customization and Adaptability

The ability to design specific tools allows companies to tailor solutions to their particular needs, improving operational efficiency.

-

Reduction of Development Leadtimes

The use of 3D printing for prototypes accelerates the validation process, enabling quick adjustments before mass production.

-

Cost-Effectiveness

The production of custom tools and accessories can be more cost-effective than purchasing standard solutions, especially when specific modifications are required.

-

Improved Production Efficiency

Tools designed specifically for tasks on the production line can reduce cycle times and increase productivity.

-

Continuous Innovation

Collaboration with engineering and production departments fosters an environment of innovation, where new ideas and technologies can be explored to enhance processes.

-

Material Versatility

The ability to manufacture with different materials, such as aluminum and steel, allows companies to choose the most suitable option for their specific needs, ensuring durability and functionality.